Be it a professional construction worker who has to sand, scrub or paint or a regular person who wants to inflate a basketball or a soccer ball, portable air compressors are the answer. They find their way from local households, to huge factories.

The following factors help you choose the perfect compressor, and they do perform well as compared to their other counterparts with the same minimum requirements. These factors need to be carefully assessed and considered before any decision regarding a change is incorporated into the industry.

- Tank capacity

It results in the compressor’s efficiency. The more is the tank capacity, the more pressurized air can it contain.

- Duty cycle

This is the factor used to measure how long can you use a compressor continuously.

- Maximum pressure

This factor states that the pressure of air should be more than required for the task at hand as it directly affects the efficiency of the compressor.

- Materials

If the compressor parts are made out of premium material, you might get charged a few extra bucks but that would mean more durability. Moreover, the concrete coatings that are required by most manufacturing plants, customised according to the industrial needs may turn out to be expensive, however, the impact and the results are favourably amplified.

Air compressors perform a lot of work and services for you depending on their type. There are 4 major types of air compressors –

- Wheelbarrow

- Pontoon

- Pancake

- Twin-stack

What does pneumatic devices have to offer?

- Source of onsite power

- Lighter and durable, especially when it is a rougher and dirty environment you are talking about.

- Versatile, because no matter what the task at hand, be it consumer, professional or industrial grade. And the best part is that producing the compressed air might be expensive but then it balances the economic issues by performing well at the production level.

- Being environmentally sound and friendly is what most industries now adhere to due to economic and political requirements. Hence this helps them function more effectively.

- No toxic emissions, and so cleanest form of energy

- Last longer as compared to their gas and electric counterparts. And the heat that is produced during their usage, there are methods available to utilise it to 94% that results in the multiple usages of the device’s working capacity.

Pneumatic devices have a wider level of applications. Tasks that feel like a burden are dealt with easily if you know a pneumatic alternative.

Nail guns

For all the good things pneumatic devices offer, they are as cheap as $50. And they are the most efficient way for applying on nailing boards and roof shingles.

Quicker paintings

What is cooler than a handy air-powered spray gun? And the outcome of using it in place of traditional ways produces a neater and finer finished surface and alternative professional finishes. This helps major projects to be completed and certified in a time-sensitive manner. Most industries prefer this option due to the efficiency of time and due to the permission of the proper allocation of resources.

Car repairs

Vehicle maintenance is a must, especially when you gave a lot of thought at the time of making a purchase. Because you invested in it, and it wasn’t pennies. An air-powered ratchet is all you need to tune up your car (and a YouTube video learning session to know how to do that.)

Their role in the manufacturing industry –

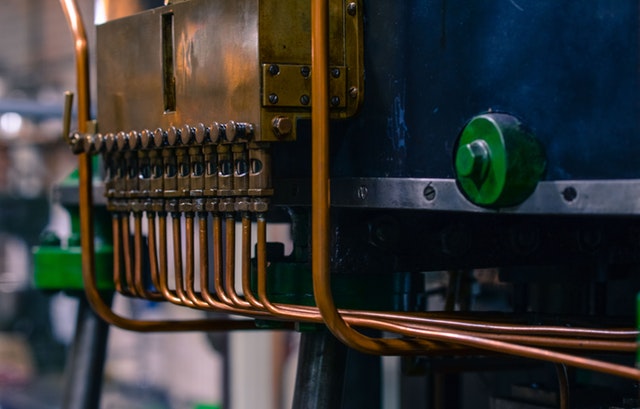

- Welding and Cutting equipment

- Operating air tools

- Discharging pieces from production moulds

- Production Monitoring by operating automated machinery

- Air cylinders also power instruments like clamps, positioners, air knives and air chucks

- Performing tasks like carton stapling, liquid padding, dry powder transporting, appliance sanding and fluidizing

- Driving screws and turning nuts

There is a lot to pneumatic devices, and they have been a part of the manufacturing industry for a long time now. They are so common that the only reason that we are unaware of them is because of our disinterest. And the most important word – “portable” is the cherry on the top of everything that the technology offers.

Pneumatic devices like these are a quick and easy way to perform many tasks. And so, it won’t be a surprise if the compressor business takes over the manufacturing completely (if it hasn’t done so already) due to the addition of this single word.

Hence these factors need to be considered when factoring in portable air compressors in the manufacturing industry and consider their pros and cons before incorporating them into any activity that the industry is specialising in. Portable air compressors can be the new thing in the manufacturing sector with more and more competitors springing up. As these competitors have started to adopt the latest and the updated techniques to up their game, it is important for every industry to catch up with the cut-throat competition and adapt themselves to avoid obsoletion.